Ultimate Guide to DTF Printing Strategies for Magnificent Textile Designs

Embarking on the journey of mastering DTF printing techniques can open up a world of opportunities for developing visually captivating textile layouts. In this overview, we will explore the elaborate details of DTF printing, from understanding the fundamental essentials to unraveling progressed shade strategies that can raise your styles to new heights.

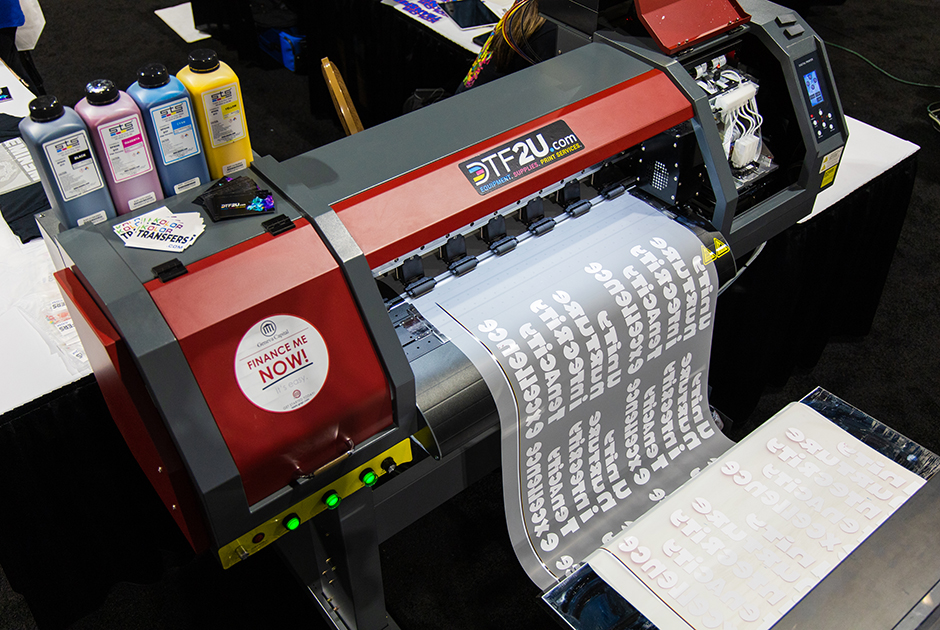

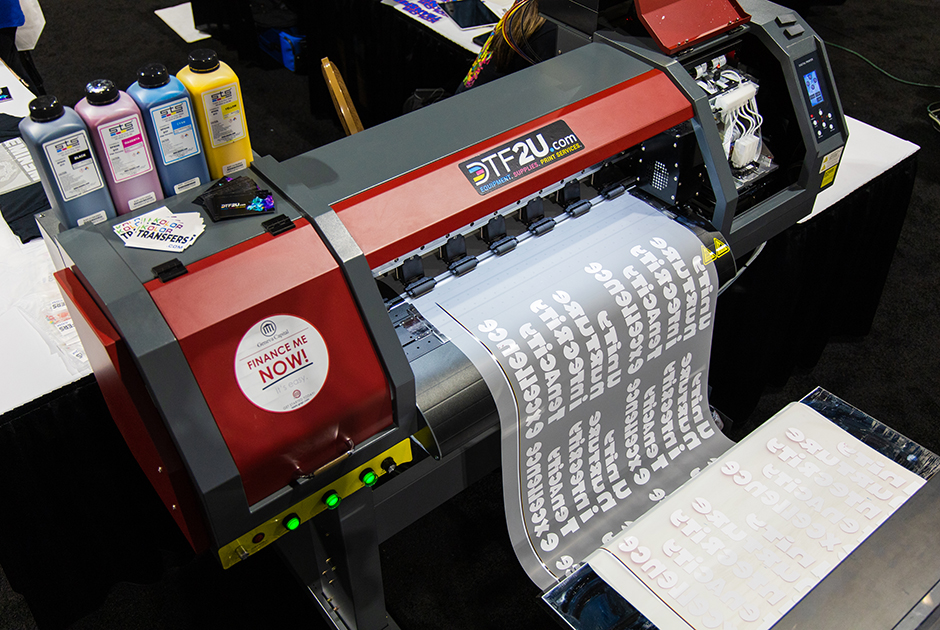

Recognizing DTF Printing Essentials

DTF printing, a procedure that entails transferring designs from an unique movie to textiles making use of heat and pressure, develops the foundation of fabric printing methods. The first action in DTF printing entails developing or selecting a layout that will be published onto the fabric.

When the design is printed on the movie, it is then meticulously positioned onto the material, making sure proper positioning and positioning. The next essential action entails applying warm and stress making use of a warm press machine. This procedure triggers the dyes or pigments on the film, triggering them to sublimate and bond with the textile fibers completely. The result is a stunning, resilient textile layout that is cleanable, adaptable, and resistant to fading. Generally, recognizing the basics of DTF printing is vital for mastering this contemporary fabric printing strategy.

Selecting the Right Textile Materials

Having established the fundamental concepts of DTF printing methods for fabric styles, the next vital factor to consider lies in selecting the suitable textile products to complement this ingenious process efficiently. In addition, the stretchability of these materials can suit the warmth transfer process included in DTF printing without misshaping the design. By choosing the ideal fabric materials, developers can maximize the capacity of DTF printing to develop long-lasting and spectacular fabric layouts.

Understanding the Printing Refine

To succeed in DTF printing methods for textile designs, understanding the printing process is necessary for attaining top notch and consistent results. The temperature, pressure, and duration of warmth application should be carefully regulated to make sure proper bond of the design to the textile. By refining each of these steps in the printing procedure, designers can continually produce durable and sensational textile designs with DTF printing strategies.

Enhancing Styles With Shade Techniques

Moreover, try out shade slopes can bring a feeling of movement and fluidity to the design. By mixing shades flawlessly, a slope effect can be achieved, including a modern-day and dynamic touch to the textile design. Additionally, utilizing color blocking strategies can produce bold and striking visuals by juxtaposing various strong colors in unique sections of the design.

Moreover, including metal or neon colors can provide a one-of-a-kind and attractive component to the textile design, making it stand out and show a feeling of vibrancy. When tactically applied, these shade techniques can boost the overall visual charm of textile layouts, making them much more unforgettable and captivating.

Troubleshooting Common DTF Printing Issues

After checking out different shade strategies to boost fabric layouts, it is important to deal with typical DTF printing concerns that might develop throughout the manufacturing procedure. In addition, problems with image clarity and intensity can take place due to low-resolution photos or inappropriate printing methods. By being conscious of these typical problems and executing the required troubleshooting steps, you can enhance the general quality of your DTF published fabric layouts.

Final Thought

In click here to find out more verdict, mastering DTF printing strategies is essential for creating magnificent fabric styles. By recognizing the fundamentals of DTF printing, selecting the right products, and boosting styles with color techniques, one can attain excellent results. It is necessary to fix usual concerns that may arise throughout the printing procedure to guarantee an effective result. With practice and focus to detail, one can create unique and lovely textile layouts making use of DTF printing techniques.

DTF printing, a procedure that includes moving layouts from a special movie to textiles utilizing warmth and stress, develops the foundation of fabric printing techniques.Having actually established the foundational concepts read review of DTF printing strategies for fabric layouts, the following vital factor to consider lies in choosing the suitable fabric products to complement this ingenious procedure properly. By selecting the best fabric products, developers can maximize the capacity of DTF printing to produce resilient and magnificent fabric designs.

To excel in DTF printing techniques for textile designs, mastering the printing procedure is crucial for attaining regular and premium outcomes. DTF Printing. By honing each of these steps in the printing procedure, designers can regularly create sturdy and magnificent fabric layouts with DTF printing methods

Comments on “Grasping DTF Printing: A Comprehensive Overview to Direct-to-Film Techniques”